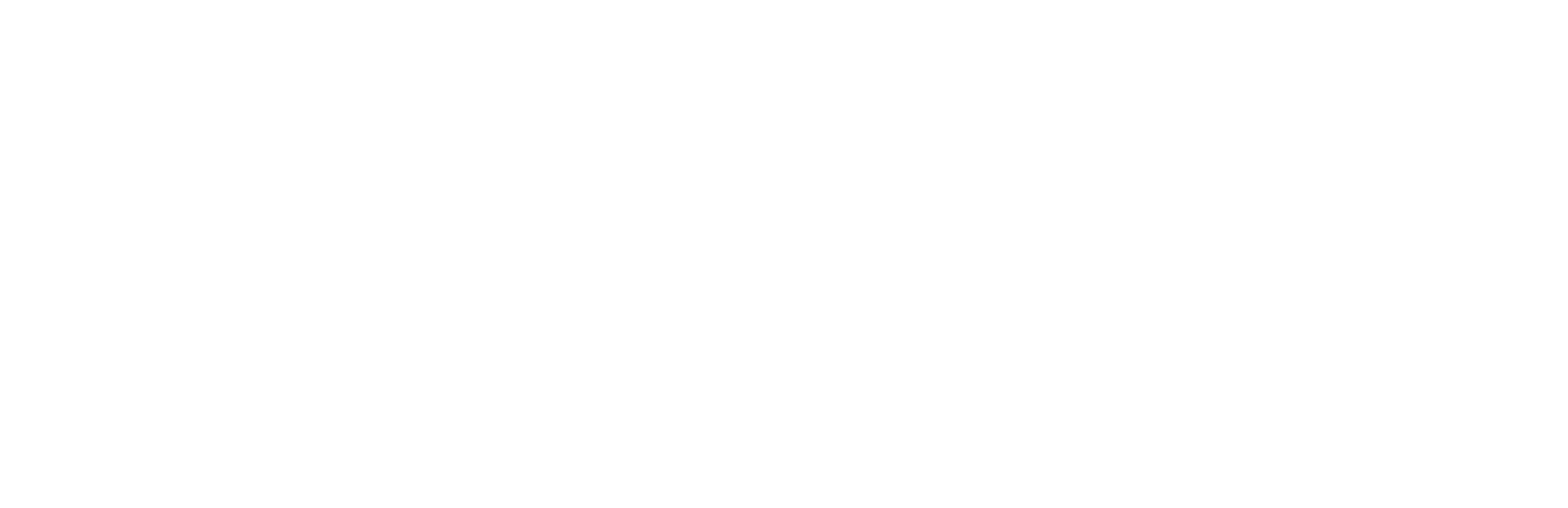

The BRI Research Winery Sauvignon Blanc has been ticking away through fermentation nicely in the new research tanks. Each day the unique 200L and 17L vessels were tested and proved to produce very clean ferments with consistent brix drops – much to the team’s pleasure. The VinWizard temperature control package has been an essential part in maintaining and monitoring fermentation and has made our job much easier.

Images: Vin-Wizard brain box; Vin-Wizard visual interface system; close up of temperature probe inserted in a 200L tank.

All wines were fermented to dryness with fermentation completed by Easter Sunday including the commercial wine at Indevin – which shows great consistency in fermentation control between the different vessels . From there the tanks were sulphured and held at 10 degrees for settling before racking off the ferment lees.

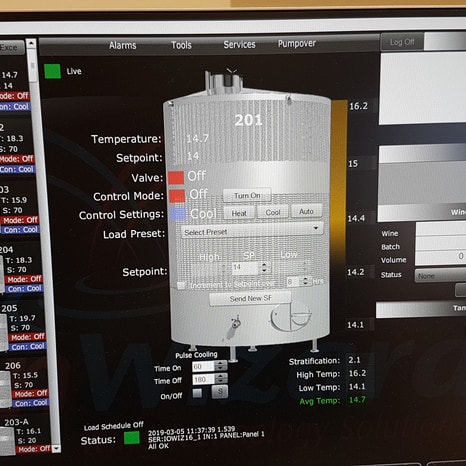

As part of the BRI winemaking protocol each wine had to be kept separate and racked on the same day. It took some time racking the 14 vessels but it all went smoothly and the team enjoyed some of the “Wine Art” created by tartrates formed during the settling period.

Images: Sauvignon Blanc Tartrates in the 200L tanks.

The timing was perfect – we got to celebrate International Sauvignon Blanc day tasting the first Sauvignon Blanc made in the unique research tanks – while it is in an unfinished state and has a little higher acidity (as not cold stabilized yet) the team think it’s excellent with definitive Marlborough Sauvignon Blanc aromatics and flavours.

We couldn’t think of a better way to celebrate the drop that Marlborough is world famous for, Cheers!!

Image: BRI Team enjoying a taste of the future – Left to Right: MJ Loza (CEO), Tracy Benge (Establishment Manager), Hayley McCairns (Marketing), Jacqui Wood (Research Winery Manager), Fang Gou (Data Co-Ordinator), Claire Grose (Research Winemaker – Plant & Food Research), Vilma Martikainen (NMIT Student), Will Kerner (Research Programme Manager)