Shan Yi, Kai Xin Chia, Wei-Qin Zhuang, Brent Young

University of Auckland

Dr Shan Yi (right) and PhD student Kai Xin Chia

The New Zealand wine industry is thriving, but with growth comes the challenge of managing grape marc waste – those leftover skins, seeds, and stems. Traditionally seen as a disposal challenge, grape marc is rich in valuable bioactive compounds and organics. While previous research has focused on extracting these bioactive compounds, the remaining organic-rich residue can also be repurposed as feedstock for chemical production, representing a promising, scalable valorisation pathway that has not been fully explored in New Zealand.

To repurpose grape marc as a carbon neutral and renewable feedstock for engineered bioprocesses, Dr Shan Yi and her research team at the University of Auckland (UoA) aimed to develop a novel biochemical engineering process to convert the bulk organics in grape marc into medium-chain organic acids using the catalytic abilities of anaerobic microorganisms. Funded by the Bragato Research Institute, this research project was also part of the PhD research of Kai Xin Chia.

Their approach entailed two specific aims: 1) to develop a treatment process that efficiently converts grape marc into fermentable organics, and 2) to construct an anaerobic microbiome, a mixture of microorganisms that catalyse the anaerobic chain elongation (ACE) reactions to convert the fermentable organics from grape marc into end products like butyric acid and caproic acid, which have substantial market demand and value. Their innovative approach seeks not only to mitigate the issues associated with disposing of grape marc and its environmental impact but also to add significant economic and social value to the New Zealand wine industry.

What is the ACE reaction?

Central to their research for valorising grape marc is the ACE reaction, a fascinating metabolism used by bacteria that thrive in oxygen-free environments. These bacteria convert simple organic compounds like ethanol and acetate into larger molecules like butyric acid and caproic acid to gain energy for growth. The UoA team harnessed the natural capabilities of these bacteria, turning them into catalysts in bioreactors to transform organics from grape marc into valuable chemicals. Because these bacteria prefer mild and oxygen-free conditions, the developed bioreactor process operates without the need for high heat or excessive power consumption, making it an environmentally friendly, low-carbon technology.

How to unlock grape marc’s potential?

The research team’s initial experiments demonstrated that soluble organic compounds in grape marc could be readily converted to butyric acid and caproic acid through bacteria-catalysed ACE reactions. However, most organics in grape marc exist as complex biopolymers like cellulose and lignin, making them inaccessible for ACE reactions. To address this, the team developed a multi-step process involving physical, chemical, and enzymatic treatments to break down these biopolymers. Under optimal conditions, they achieved over 80% release of organics from the biopolymers, effectively unlocking the grape marc for bioconversion.

How does this grape marc upcycling bioprocess work?

Starting with seed material from an anaerobic digester at a local wastewater treatment plant, the team enriched an ACE microbiome containing a mix of bacteria that consistently produced target

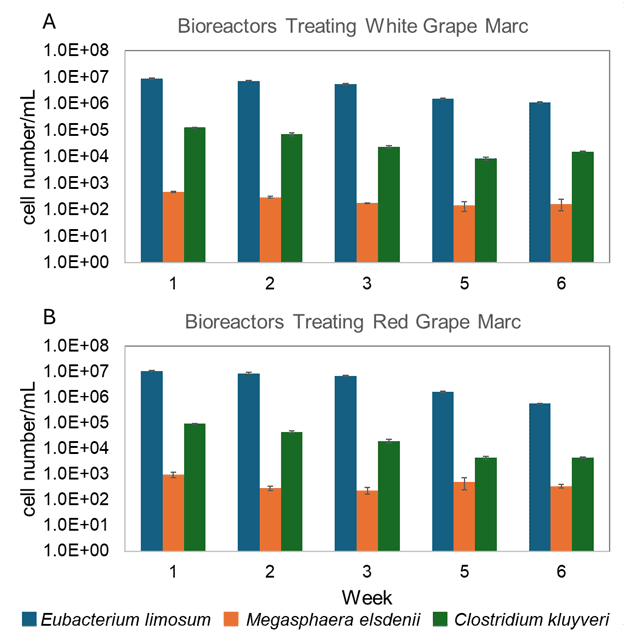

products at high concentrations, reaching 10 to 12 g/L of butyric and caproic acids. This well-performing ACE microbiome was then used in a lab-scale bioreactor to treat grape marc organics from the multistep process. After the bioreactor operational conditions were optimised, the production of these acids was monitored, confirming the process’s effectiveness. To ensure the reliability of this innovative bioprocess, the team also monitored the populations of three key ACE bacterial strains over six weeks using quantitative PCR. This sensitive molecular technique revealed that the bacteria had adapted well to the bioreactor conditions, maintaining stable cell numbers and consistent performance (figure 1).

Figure 1. Three ACE bacteria numbers detected in the bioreactors converting organics from white (A) and red (B) grape marc.

Figure 1. Three ACE bacteria numbers detected in the bioreactors converting organics from white (A) and red (B) grape marc.

Is this bioprocess economically viable?

A crucial aspect of this research was its economic feasibility. The biochemical engineering process developed consists of two main units: a multi-step treatment to convert grape marc into fermentable organics and bioreactors with the ACE microbiome to transform these organics into caproic acid and butyric acid. Considering the conversion rates achieved in their laboratory-scale process and the seasonality of grape marc production, the team conducted a comprehensive techno-economic analysis. The results show that this biochemical process offers a significant economic advantage, outperforming traditional valorisation methods like pyrolysis and anaerobic digestion. The value generated can sufficiently offset bioprocessing costs and greatly enhance the value of the wine industry’s byproducts.

Impacts to the New Zealand wine industry

Sustainably repurposing grape marc is increasingly urgent for the New Zealand wine industry. Conventional methods like composting, land application, or landfilling offer limited economic benefits and pose potential environmental risks, such as greenhouse gas emissions and the leaching of organic compounds into soil and waterways. In contrast, valorising grape marc through a biorefinery approach – converting biomass into a variety of valuable products – can yield better financial and environmental outcomes. The biochemical process developed in this research can be used as a standalone method or as part of a larger biorefinery system. Integrating this bioprocess into the wine production chain could help wineries achieve low-waste operations, significantly enhancing their sustainability profile and bolstering the reputation of the New Zealand wine industry as a leader in environmental stewardship.

Additionally, the production of butyric and caproic acids from grape marc benefits not only the wine industry but also other sectors in Aotearoa, New Zealand. This innovative research could significantly contribute to a more sustainable and prosperous future.

Conclusion and future prospects

In this research, Shan and her team successfully developed an innovative bioprocess to convert grape marc into valuable chemicals, addressing intricate environmental and economic challenges. The next stage will focus on the engineering questions related to scaling this laboratory bioprocess to the pilot stage. The team is also seeking industrial partners interested in collaborating on further investigations and the technology transfer of this novel bioprocess. Please contact shan.yi@auckland.ac.nz if you are interested in partnering.

This research not only transforms waste into valuable products but also reshapes our understanding and use of biomass, paving the way for a more sustainable future in the New Zealand wine industry.

About the project

Led by Dr Shan Yi and funded by Bragato Research Institute, this two-year project aimed to develop a novel anaerobic chain elongation (ACE) bioprocess to convert grape marc waste into valuable organic acids. By utilising a specialised microbiome in bioreactors, the developed ACE bioprocess supports the sustainability and economic growth of the New Zealand wine industry. This project was conducted in the Department of Chemical and Materials Engineering at the Faculty of Engineering at the University of Auckland.