Dr Paul Epee, Bragato Research Institute

Rising costs of production, together with falling profitability, warranted investigation into the potential for a step change in the productivity of winegrowing. As part of the seven-year Next Generation Viticulture research programme, field trials were established in three Marlborough vineyards starting in winter 2022, to explore alternative ways of growing grapes in New Zealand.

Sauvignon Blanc, the New Zealand wine industry’s iconic white grape variety, was studied alongside four other varieties – Riesling, Albariño, Pinot Noir, and Lagrein. These trials aimed to investigate the potential of alternative training systems by reducing management costs and raising vineyard returns. The first article of the series, published in the previous issue of this magazine (Issue 149), reported the results of these trials from budburst to veraison.

Six training systems were compared to the traditional head-cane VSP (or commercial control) practised on Sauvignon Blanc. All six new training systems had significantly higher retained node numbers ranging from two- to twelve-fold that of the commercial control. They developed their foliage early in the growing season and covered the trellis faster, thus capturing more sunlight radiation early in the season. Although all seven training systems had similar exposed leaf areas, some grew a denser canopy (measured by leaf layer number), while others had a canopy density similar to the commercial control. Of all six alternative training systems, one stood out for its potential to carry more nodes (twice the control) without adversely affecting budburst and canopy density. This article considers the effects of these training systems on the vine’s reproductive growth, fruit maturity, yield, vine balance ratios, retained biomass and vine vigour.

Vineyard description, training systems and measurements

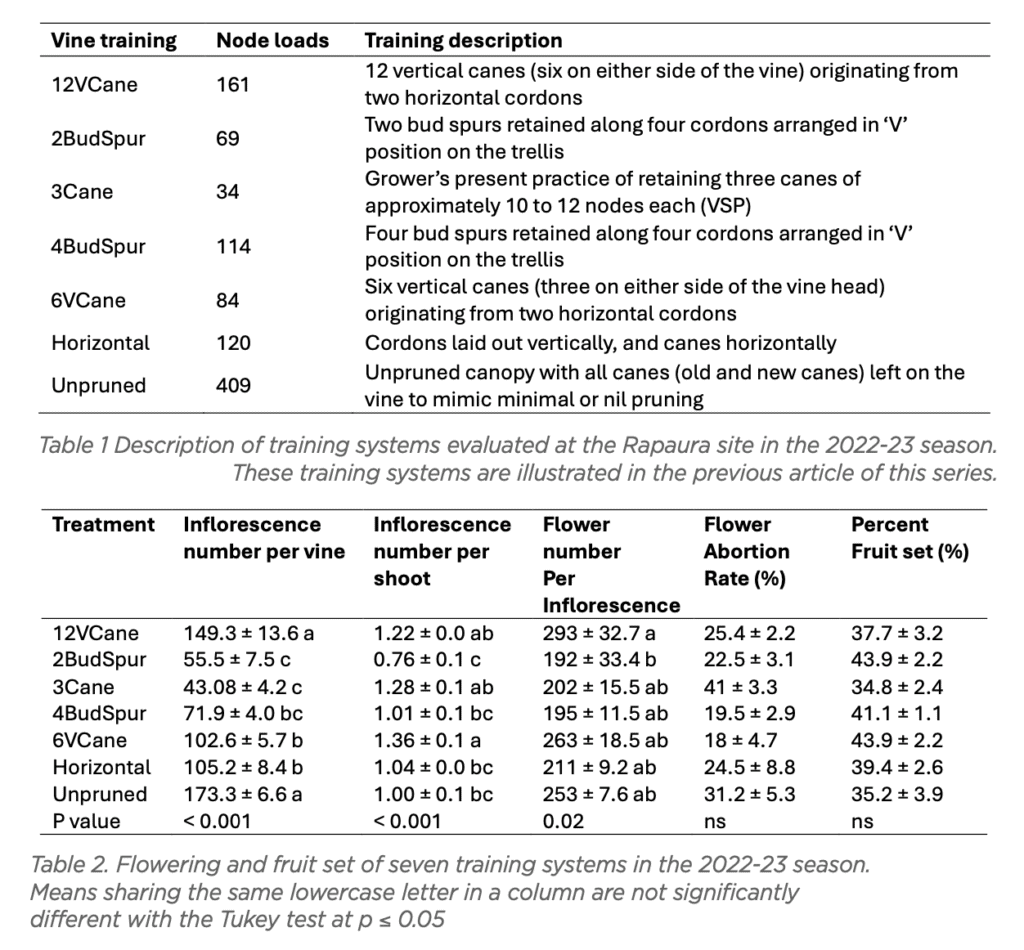

The trial was established in a vineyard block northwest of Blenheim (Rapaura) and planted in the late 2000s. A detailed description of the trial site and the vine training treatments (Table 1) is presented and illustrated in the previous article (New Zealand Winegrower Issue 149). In brief, the vineyard block was planted to Vitis vinifera cv. Sauvignon Blanc grafted on an unknown rootstock genotype at 2.7 m row spacing and 1.8 m vine spacing. The vines were pruned in early September 2022 according to the seven training treatments (Table 1). Once visible, inflorescences were counted on two data vines per bay.

To assess flowering and fruit set, mesh bags were fitted on two inflorescences per vine in early November 2022 at the beginning of flowering, then removed in late January 2023 just before veraison. The content of the mesh bag (green bunches, aborted flowers, flower caps, bag label) was emptied into a tray, then green berries, live green ovaries (LGO) and aborted flowers were separated from the rachis, weighed and counted. The number of flowers per inflorescence was obtained by summing the number of green berries, LGOs and aborted flowers. The flower abortion rate was calculated by dividing the number of aborted flowers by the total number of flowers per inflorescence and the fruit set percentage by dividing the number of green berries by the total number of flowers per inflorescence. The number of inflorescences per shoot was obtained by dividing the number of inflorescences per vine by the vine’s shoot count.

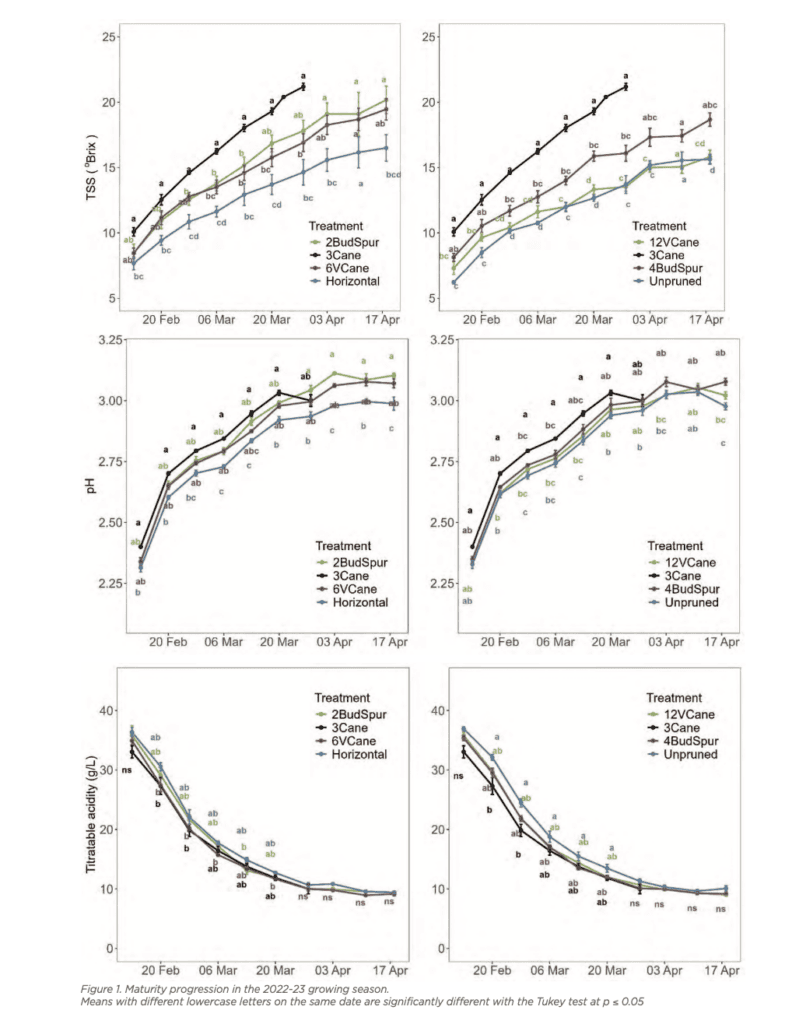

From veraison to harvest, 30 berries were sampled weekly per bay (on four vines). For 6VCane, 12VCane, Horizontal and Unpruned treatments, an equal number of berries (15 berries) was sampled at the lower part (from zero to 50 cm above the bottom fruiting wire) and higher part (from 50 cm to the top) of the canopy. Samples were processed within 48 hours for total soluble solids (TSS), titratable acidy (TA) and pH. Logarithmic and logistic growth functions were fitted to estimate maturity duration – i.e., days from TSS 8 to 21°Brix (logarithmic model), TA 35 to 9 g/l and pH 2.35 to 3.1 (logistic model).

Vines were planned to be harvested at the target TSS of 21°Brix. However, due to weather conditions, crop levels and disease pressure that year, some treatments were harvested before they reached the target TSS. Vines were hand-harvested by cutting and collecting whole bunches into crates. Bunches were counted and weighed. After leaf fall, dormant shoots were counted and six were sampled per vine to characterise their morphology (diameter, length, node number and internode length). In winter, all vines were pruned according to their training systems. On 3Cane vines, one-year-old and two-year-old wood were pruned off and weighed separately. The Unpruned treatment was trained back to the head-cane VSP system similar to the control treatment whenever possible. On the other treatments (6VCane, 12VCane, Horizontal, 2BudSpur and 4BudSpur), one-year-old wood (canes) were removed retaining four buds spurs for 4BudSpur trained vines and two buds spurs for the rest of the treatments. Canes were weighed, and the remaining wood (vertical and horizontal cordons) was estimated by measuring individual cordon volumes and multiplying that value by the wood density.

Flowering and fruit set

Flowering and fruit set varied greatly between training treatments. The total number of inflorescences per vine was directly related to retained node numbers, with 12VCane and Unpruned vines carrying significantly more inflorescences (Tables 1 and 2). The number of inflorescences per shoot followed a different pattern unrelated to the retained node number. 2BudSpur and 4BudSpur had the first and second lowest number of inflorescences per shoot. Because these vines were spur-pruned, lower node positions on canes were selected, and these nodes are thought to have lower fruitfulness as they usually carry fewer inflorescence primordia. Interestingly, these two treatments also had the lowest number of flowers per inflorescence (Table 2), suggesting that fruitfulness is a function of the number and the size of inflorescence primordia. Horizontal and Unpruned vines had the second and third lowest inflorescence per shoot, whereas 6VCane had the highest, followed by 3Cane and 12VCane. Flowering and fruit set were comparable across all training systems (74% and 40%, respectively) despite a trend toward a higher flower abortion rate on 3Cane vines.

Berry maturity and harvest

TSS accumulation was the fastest throughout ripening on 3Cane vines (Figure 1), taking 43 days to go from 8 to 21°Brix. 3Cane vines were harvested on 28 March 2023 at 21.1 °Brix. The second and third shorter ripening periods were observed on 2BudSpur and 6VCane vines with ripening durations of 77 and 87 days, respectively. 2BudSpur and 6VCane were harvested on 18 April 2023 at 20.2 and 19.5 °Brix, respectively. Treatments accumulating TSS at the slowest were 12VCane, Unpruned and Horizontal, with a ripening duration of 131, 114 and 112 days respectively.

pH increased steadily across all treatments except for Unpruned and Horizontal, where the increase was significantly slower. The days from pH 2.35 to 3.1 were not significantly different between these two treatments (~65 days) but were the longest compared to other treatments. That duration was the shortest for 2BudSpur vines (42 days) and shorter for 4BudSpur, 3Cane and 6VCane (~55 days).

The drop in berry juice TA varied little across all training treatments (Figure 1). However, because 3Cane was harvested earlier (28 March 2023), it had the highest TA (10.5 g/l), whereas all other treatments had around 9.2 g/l. The days from TA 35 to 9 g/l were not significantly different across the seven training treatments, ranging between 47 and 51 days.

There was very little to no variation in the chemical composition (TSS, TA, pH) of berries sampled at the top and bottom part of the canopy for 6VCane, 12VCane, Horizontal and Unpruned vines. 12VCane showed some differences between TSS of top and bottom berries on 13 – 28 March 2023 but disappeared at the end of the maturity period (3 – 18 April 2023). A similar pattern was observed in pH for 12VCane and 6VCane treatments. Overall, berry maturity was uniform on the whole canopy. This was an interesting result because these training systems (i.e., 6VCane, 12VCane, Horizontal and Unpruned) required spreading the fruiting zone over the whole canopy. This raised considerations about differential bunch maturation, as bunches at the top half of the canopy could possibly mature faster due to distal shoots growing more vigorously early in the season and carrying more leaves than proximal shoots at the bottom half of the canopy. However, all bunches reached the same maturity by harvest time.

Yield components and source- sink relationship

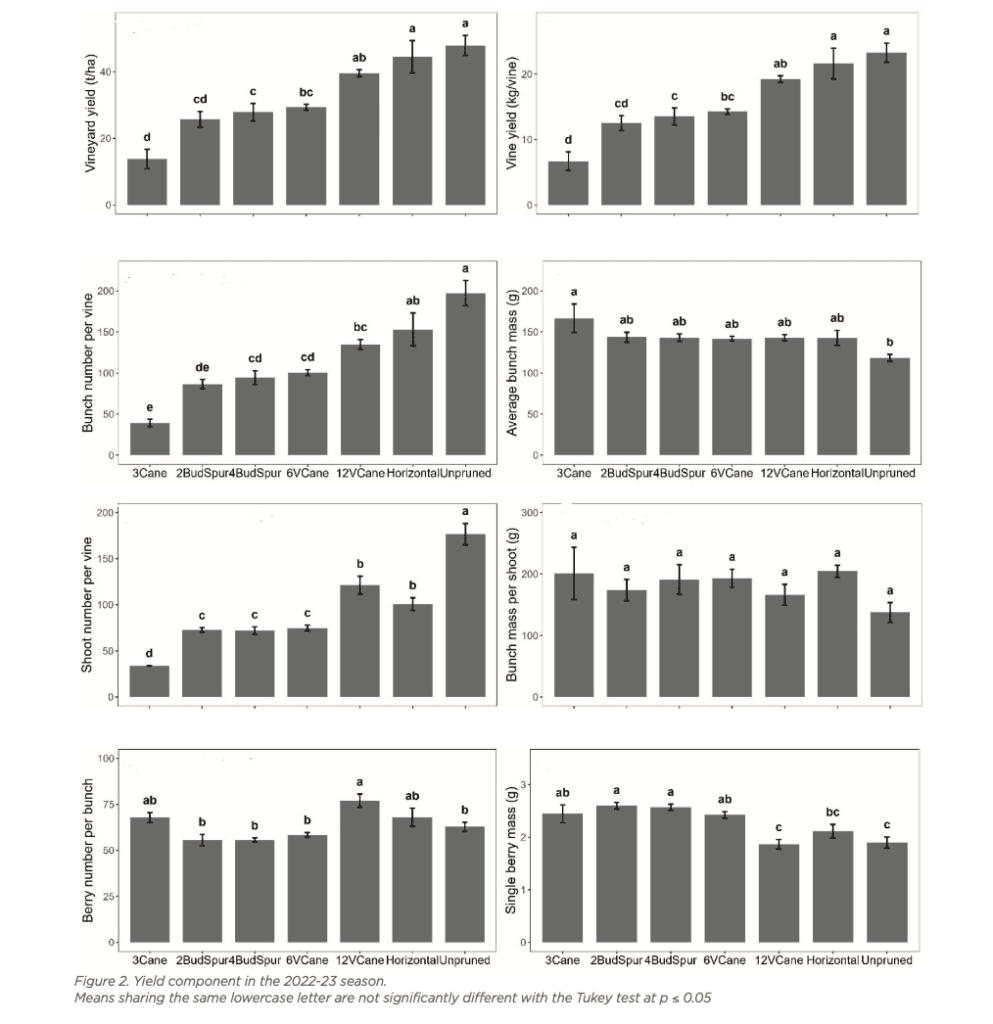

The yield and bunch number per vine were linearly related to both retained node and shoot numbers, and training systems with higher node and shoot numbers produced more fruit per vine and hectare (Figure 2). 3Cane vines had the lowest yield (13.8 t/ha) and Unpruned the highest (47.9 t/ha), almost 3.5 times the commercial control, followed by Horizontal (44.5 t/ha) and 12VCane (39.6 t/ha). Intermediate yields were measured on 2BudSpur, 4BudSpur, and 6VCane, respectively, at 25.7, 27.8, and 29.3 t/ha. However, 6VCane yielded significantly more than 2BudSpur and 4BudSpur for a comparable number of shoots per vine.

Bunch morphology was greatly affected by training systems. On 2BudSpur and 4BudSpur vines, bunches had intermediate mass (143 g), with significantly bigger but fewer berries; 3Cane vines had bigger bunches (166.8 g) carrying both bigger and more berries; unpruned vines had very small bunches (118.5 g) carrying fewer and smaller berries. Of all yield components, bunch mass per shoot was the most stable, followed by the average bunch mass and berry number per bunch.

The analyses of the source-sink relationship (i.e., exposed leaf area to fruit mass ratio – ELA/FM) revealed that all training systems except the 3Cane commercial control had low or very low source-sink ratios. It has been shown that the lower the source-sink ratio, the slower the TSS accumulation. Admittedly, Unpruned, Horizontal and 12VCane took significantly longer to reach 21°Brix (>110 days) and pH 3.1 (>65 days). Trying to achieve the maximum yield within the limits of the existing trellis and management system at that site came at the expense of adequate fruit composition. However, when the three highest-yielding training systems were excluded (i.e., Unpruned, Horizontal and 12VCane), there was no clear relationship between the source-sink ratio and the other two maturity components (TA, pH). The days required to reach pH 3.1 and TA 9 g/l were not statistically different, ranging from 49 – 57 days for pH and 47 – 51 days for TA.

The higher-yielding training systems (2BudSpur, 4BudSpur and 6VCane) had an ELA/FM of 0.5 m2/kg, which might be considered suboptimal compared to 1.2 m2/kg for 3Cane. However, a recent study* found that a source-sink ratio of 0.75 m2/kg was sufficient to bring New Zealand Sauvignon Blanc grapes to the desired maturity. Therefore, slightly adjusting the crop level at pruning the following winter would bring the source-sink closer to the desired ratio with positive outcomes for sugar accumulation. It is also important to note that with the 6VCane training system, the intention is to extend the height of the annual vine canopy to about 2.2 m in subsequent years. This will increase the total ELA with positive effects to sugar accumulation rate.

Vigour characteristics and retained biomass

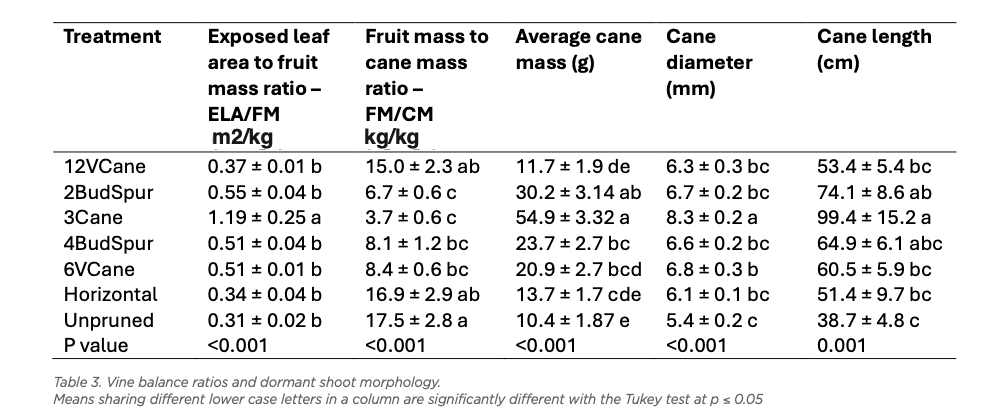

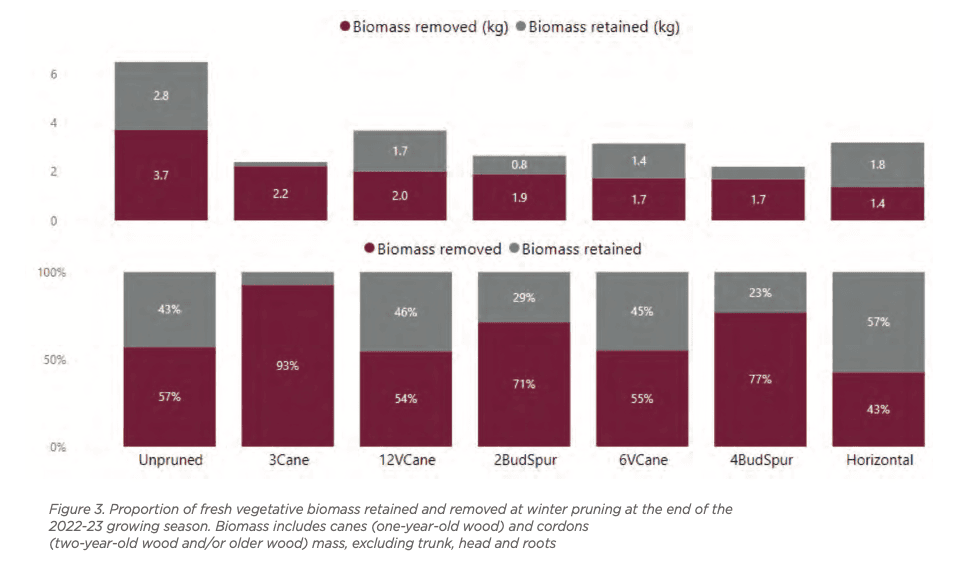

Vigour was highest on 3Cane vines with significantly longer, stockier and heavier canes than other treatments (Table 3). Despite carrying the lowest number of shoots, 3Cane vines had the highest one-year-old wood or total cane mass (1.7 kg). Vigour control through alternative training systems was one objective of this study because managing excess vigour in the vineyard is costly. 6VCane and 4BudSpur shoots had intermediate vigour, with Unpruned, Horizontal and 12VCane falling at the lower end of the vigour spectrum. The latter vines also had the highest fruit mass to cane mass (FM/CM) ratio (>15 kg/kg). The FM/CM indicates the balance between vegetative and fruit growth and values falling between 5 and 10 kg kg-1 are considered optimal for most grape varieties. A recent study* on Sauvignon Blanc showed that FM/ CM of 3 – 6 kg/kg was adequate at some New Zealand Sauvignon Blanc vineyard sites on head-cane VSP training systems. With our current understanding of the optimal vine balance metrics it may seem that vines with an FM/CM above 10 kg kg-1 were overcropped. However, as these vines under the new training systems reach stability over the years (i.e. have a fully developed canopy with well-established horizontal and vertical cordons), vine balance ratios (ELA/FM and FM/CM) presently understood to be optimal could become irrelevant or inappropriate under the new training systems. The proportion of biomass retained versus removed at winter pruning was another distinctive feature of the seven training systems. Of all seven training systems, 3Cane, 4BudSpur and 2BudSpur produced the least vegetative biomass (canes and cordons), but 3Cane only retained 7% of its canopy biomass, the lowest, versus 23% and 29% for 4BudSpur and 2BudSpur respectively (Figure 3). With cane pruning, nearly 95% of the annual growth is removed, constituting an immense biomass loss for the vine. Horizontal, 12VCane and 6VCane had the three highest percentages of retained biomass; the higher the number of cordons, the larger the amount of retained biomass (Figure 3). For instance, 2BudSpur and 4BudSpur had the lowest number of cordons (four), and they only retained less than 1 kg biomass, whereas Unpruned, HORIZONTAL, 12VCane and 6VCane (with ~40, 18, 14 and eight cordons respectively) retained more biomass. Except for Unpruned vines, which underwent an atypical pruning regime, and 3Cane vines which were cane-pruned, the rest were spur-pruned. With spur pruning, only one-year-old wood is removed, keeping older woods on the vine, thus promoting more retained biomass. Granted, retained biomass contributes to carbohydrate reserves and resilience to frost and other abiotic stresses. With potentially more carbohydrate reserves, these vines were in a better position to support early shoot growth after dormancy the following spring.

Key takeaways from the first season of conversion to new training systems

The first season of this investigation into new training systems to lift New Zealand vineyard productivity was rich in information, learnings and lessons. The potential of seven training systems was examined, and the new training systems had significantly higher retained node numbers than the traditional 3Cane commercial control. They actively developed more shoots shortly after budburst, thus harvesting more sunlight radiation. They produced significantly more fruit despite a longer ripening period than the control. Finally, these training systems grew and kept more biomass. Of all six alternative training systems, 6VCane stood out for its potential to carry more nodes, shoots, inflorescences, fruits, and retained biomass. Throughout the growth stages, 6VCane and, in some cases, 2BudSpur almost always sat in the middle or at the optimal position in the spectrum. At budburst, 6VCane vines had the optimal budburst percentage, and at veraison, the canopy density was no denser than the 3Cane commercial control despite carrying twice its shoot number.

Removing every second shoot along upright cordons was decided to further reduce canopy density. Doing so will also bring ELA/FM and FM/CM ratios to levels conducive to optimal ripening. These interim outcomes make it clear that modifying the vine training system can considerably alter vineyard productivity potential. The capabilities and properties of the most promising training systems will be refined over the coming seasons to ensure that fruit grown is of the type, style, and quality required by wineries.

*Epee, P. T. M., Schelezki, O., Trought, M. C. T., Werner, A., Hofmann, R. W., Almond, P., Charters, S., & Parker, A. (2024). Effects of retained node numbers on berry maturity and yield components of cane-pruned Sauvignon blanc. Oeno One, 58(3). https://doi.org/10.20870/oeno-one.2024.58.3.7930

Acknowledgement

This article was prepared with the contribution of Dr Fang Gou, Bragato Research Institute Data Manager, who analysed the data, and Dr Stuart Tustin, Next Generation Viticulture Science Advisor, who reviewed the article.

About the project

The Next Generation Viticulture Programme is a seven-year programme that is a partnership between the Ministry for Primary Industries, New Zealand Winegrowers, and seven wine business co-investors contributing cash and in-kind. Bragato Research Institute is contracted to deliver the programme. The programme’s vision is to increase vineyard productivity without compromising wine quality or the environment.