February brought about an exciting milestone for the Bragato Research Institute (BRI), with the arrival of the first of our world-leading custom-designed research fermentation tanks. The arrival of the tanks signified the culmination of a year of hard work and collaboration between a team of experts across an array of disciplines. This broad-reaching collaboration has resulted in a world-first, bespoke experimental tank design. With the tanks now delivered and installed, our new unique tanks are a progression from vision to vessel.

It all started a year ago with a vision to develop a world leading research winery and unique tank design.

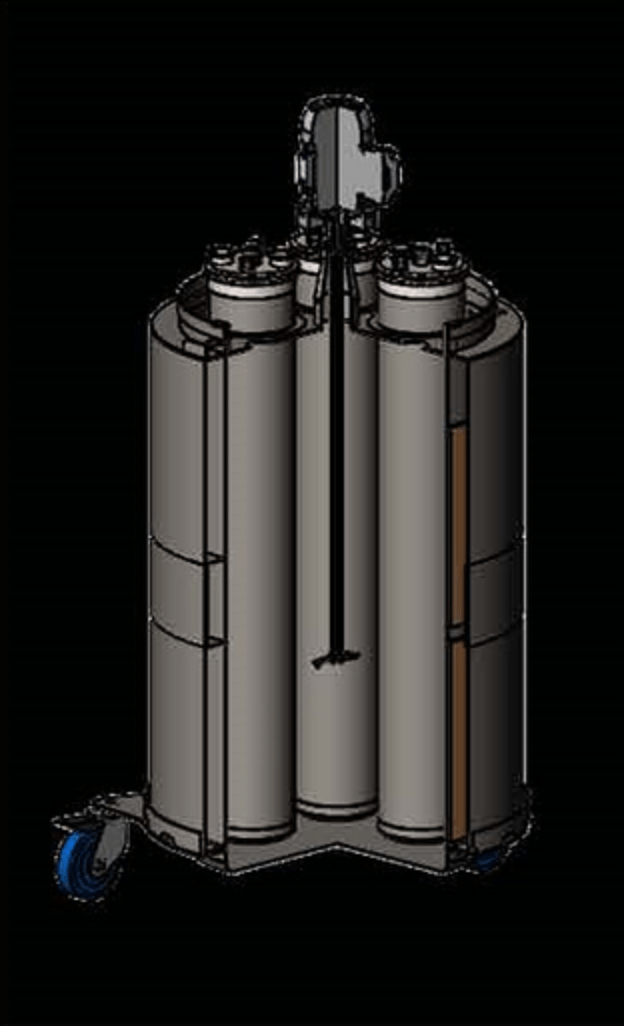

The beginnings of the vision (above)

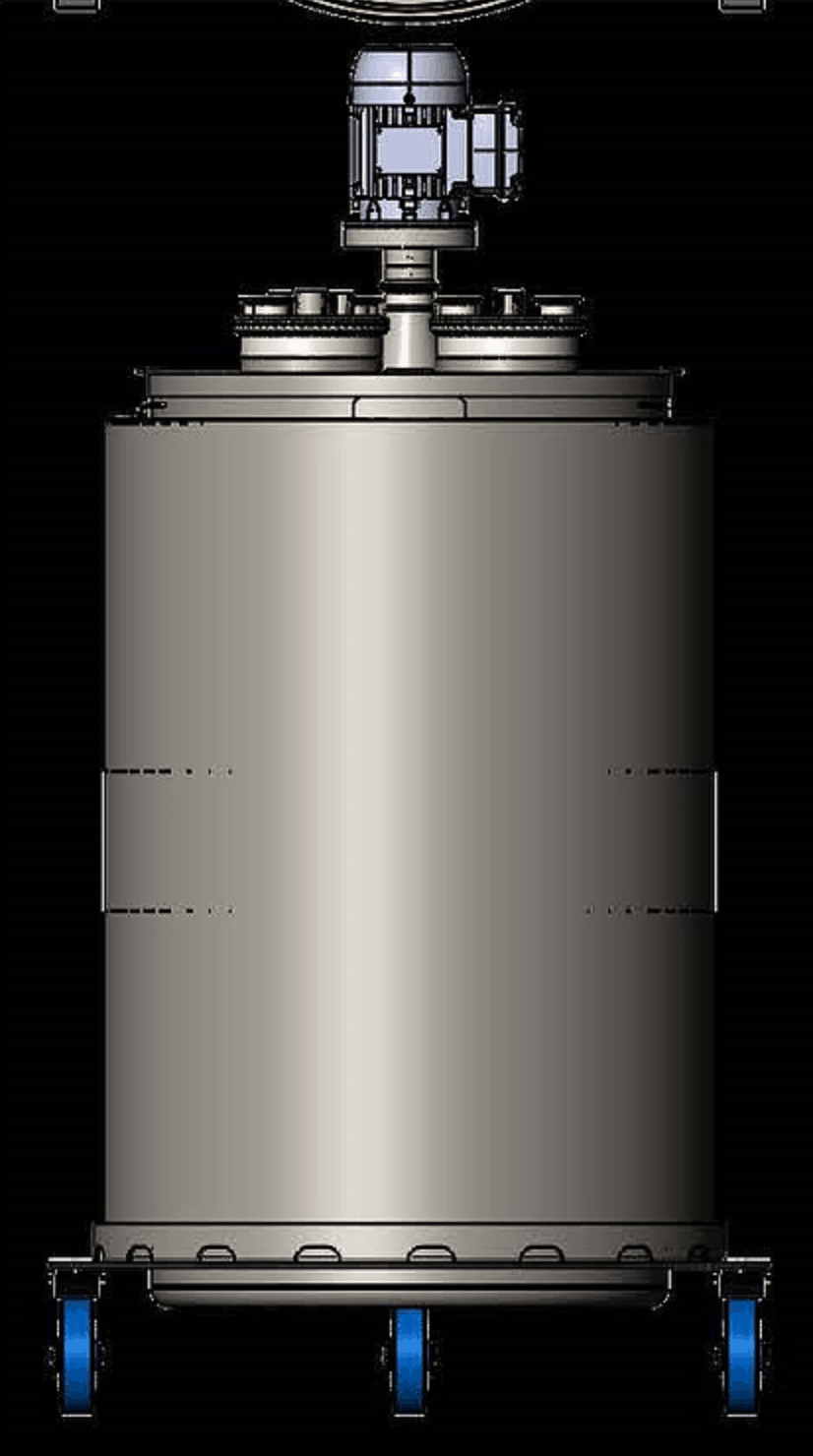

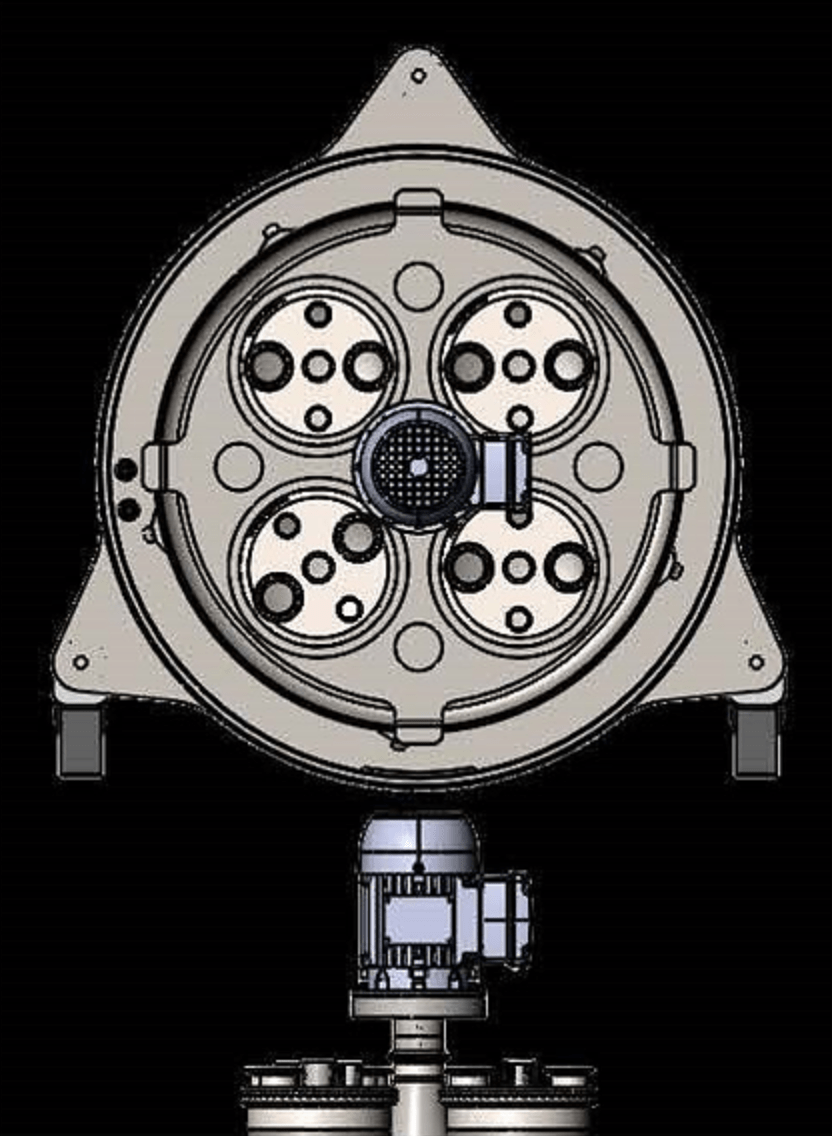

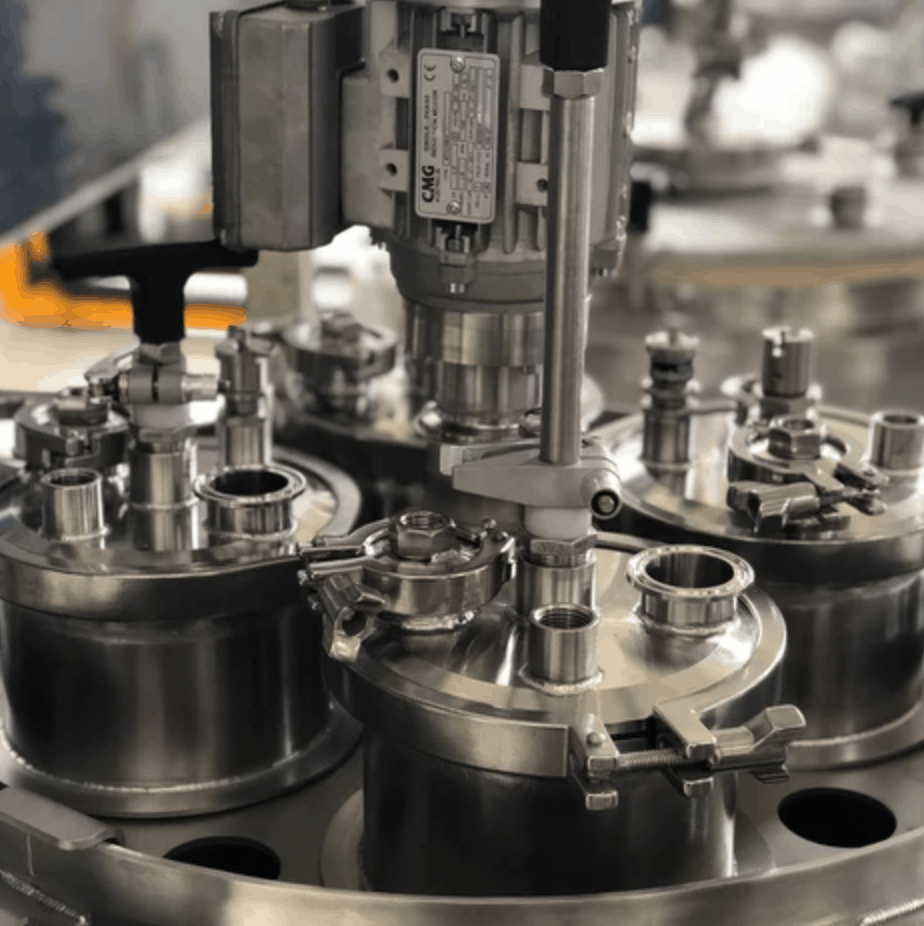

It is the tanks’ dual-purpose design and setup that makes them unique. Each tank can hold 200 litres and can be used for a single fermentation or have four smaller (17 litre) tanks inserted to house four individual fermentations, all controlled under the same conditions. This is an important aspect of the tank design, reducing variability between fermentations and providing greater validity to results in trials. Repeatability and trial setup were the driving forces behind the decision to have the four inserts. With most research requiring triplicate fermentations, the BRI tanks have offset the risk of losing statistical strength by incorporating a fourth tank in case of a mishap like a stuck fermentation. Once fermentation trials are completed, the inserts can be removed and the tank returns to a 200-litre capacity vessel, suitable for another trial, blending or storage of larger volumes if required.

Both the 200-litre tank and the 17-litre tank inserts have been designed to ferment either white or red wine, allowing further adaptability. When the 17-litre tanks are fermenting white wine, they will have an agitator insert in place and when fermenting red-wine this will be replaced with a plunger. All tanks will have automated Brix and Temperature probes, maintaining optimal temperature control and real-time data analysis. This new data analysis and control interface system is the latest technology development by Vin-Wizard.

Left to right: Arrival of a 200L tank with it’s four 17L inserts; connecting the tanks in the temporary Research Winery facility; Tracy Benge and Will Kerner from BRI checking out the mini plungers.

BRI would like to take this opportunity to thank the project working group, spanning both industry and research, who have contributed their time and expertise to bring this to fruition. They are:

- Andy Frost (Pernod Ricard)

- Heath Stafford (Indevin Wines)

- Marcus Wright (Lawsons Dry Hills)

- Claire Grose and Damian Martin (Plant & Food Research)

- Peter Mann (ProMann Consulting)

- Carl Butler and Crichton Purdie (Crown Sheet Metal)

- The teams at Hydramech Plumbing and Martella Electrical

- Adam Walker and Don McKay (Structex Engineering)

- Simon Hall (JTB Architects)

- David Gill (VinWizard)

- The research winemaking teams at UC Davis and E&J Gallo, California