Mechanical shaking for rot reduction

Crop losses from Botrytis cinerea are a problem for grape growers worldwide, including most viticultural regions in New Zealand. Grape berries are not very susceptible when unripe, and lose their resistance to infection as they ripen (Kretschmer et al., 2007). Botrytis can infect the bunch at flowering, when the floral parts and unpollinated berries abscise after set. If this “trash” is retained in the bunch, it serves as an inoculum source for the fruit. Infection can then spread throughout the bunch, especially if the bunch is tight.

Conventional control practice for botrytis involves the spraying of synthetic single site chemicals, such as fenhexamid, fluazinam, cyprodinil, and fludioxonil at flowering and before bunch closure. However, these sprays are extremely expensive, and have been shown to have negative effects on animals, plants, and the environment (Tomlin, 2009). Organic growers do not have the synthetic spray option and rely on biological sprays. A way to reliably control botrytis without any sprays would benefit all growers in NZ.

A technique recently developed in New Zealand uses mechanical harvester after set and before bunch closure (when the berries are between peppercorn and pea size) to shake the vines and remove the floral “trash” from the bunch so that it cannot serve as an inoculum source. The trauma of shaking might also thicken or toughen berry skins, or activate biochemical pathways for antifungal compounds, therefore improving the berry’s inherent resistance to botrytis infection. Mechanical shaking, used alongside standard botryticides, has been shown to reduce rot at harvest by around 50% (Haywood and Allen, 2017; Trought, 2014), however effects of shaking on berry skin toughness and biochemical responses have not been determined to date.

New study

A new study, begun this season, is striving to answer a few open questions from the research thus far. Namely, can a single shake replace two sprays, how critical is the time of shaking to achieve botrytis control, and does shaking induce tougher berry skins? The study is being carried out in three Chardonnay vineyards in Gisborne and Hawke’s Bay, and in three Sauvignon blanc vineyards in Marlborough. The trials in Gisborne and Hawke’s Bay are relatively straightforward, with vines receiving a standard botryticide spray programme but not shaken being compared with vines that are shaken but receive no Botrytis specific chemical sprays. The Marlborough trials are a bit more complex, with shaking of separate groups of vines at three different times between set and veraison. None of the shaken vines received botryticide sprays, and they were compared with vines that received a standard spray programme but no shaking. The aim of the Marlborough trial was to assess how wide the “window of opportunity” is during berry development for shaking to be effective in reducing rot.

All previous New Zealand Winegrowers studies have carried out shaking in addition to a standard botryticide programme. A major focus in this new project is to see how well shaking can replace synthetic sprays for botrytis control. This new trial is also employing a more robust measurement of rot, assessing rot severity (% of berries affected) on every bunch on treated vines, rather than a subset of bunches as has been done previously. This was done in an attempt to give a truer representation of botrytis severity in the vineyard as a whole, and give a more realistic measure of what would arrive at the winery. In all trials, vines that were shaken, but not sprayed with botrytis specific chemicals were compared with vines that received sprays at flowering and prebunch closure but were not shaken.

The shaking in the three Gisborne vineyards was done on 12 December, and the three vineyards in Hawke’s Bay were shaken on 14 December, when fruit was between peppercorn and pea size (E-L stage 30, 31). In the three Marlborough Sauvignon blanc vineyards, individual rows of vines were shaken at three different times: just after set (Shake 1: 19-20 December, E-L stage 28, around 5 g bunches), around pea sized berries (Shake 2: 11-12 January, E-L stage 31, 20-50 g bunches, Figure 2), and just before bunch closure (Shake 3: 21-23 January, E-L stage 32, 60-70 g bunches, Figure 3).

In Hawke’s Bay and Marlborough, berries were assessed for skin toughness at three times (postveraison, midripening, and harvest) using a fruit penetrometer with a 2 mm probe tip on 100 attached berries per treatment. In one Hawke’s Bay vineyard (HBCH2), control vines were left that were neither sprayed nor shaken to see how both treatments compared to doing nothing. Skin toughness was only assessed in the control berries at harvest, but was assessed for the shaken and sprayed vines three times during ripening.

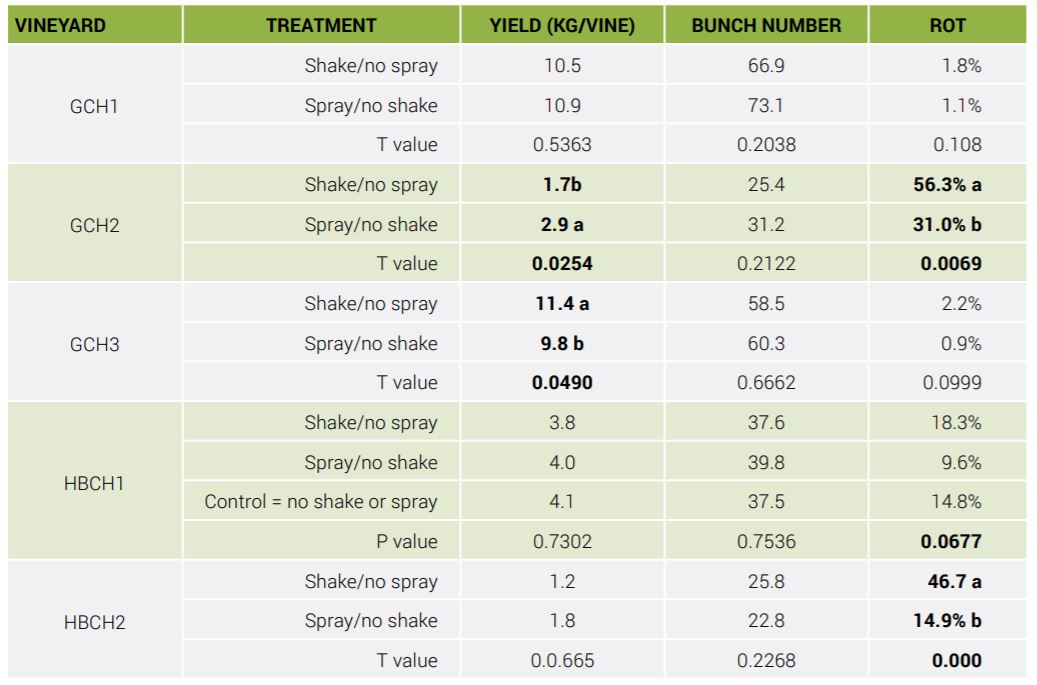

For the three trial sites in Gisborne there was no effect of shaking on bunch number at harvest (Table 1). Yield results were mixed, with one vineyard having reduced yield from shaking, one having increased yield, and one not having yield affected (Table 1). At all three sites, there was higher rot severity in the shaken only and no spray versus the spray treatment with no shaking.

In Hawke’s Bay one vineyard was harvested before analyses of yield, bunch number, and rot could be done. At the remaining two sites there was no effect of shaking on bunch number or yield. In both vineyards the vines that were shaken only and no spray had substantially more rot at harvest than those that were sprayed and not shaken (Table 1). In the HBCH1 vineyard the shaken only and no spray vines had similar rot at harvest as the control (neither shaken or sprayed), with the sprayed and not shaken vines having lower rot severity than either other treatment (Table 1).

Table 1: Harvest yield, bunch number, and average rot severity of every bunch from Chardonnay vineyards. GCH denotes Gisborne vineyards and HBCH denotes Hawke’s Bay vineyards. Values in bold with different lower case letters from the same vineyard denote significant differences at the p=0.05 level. At HBCH1 some vines were left unsprayed and unshaken, which are denoted by the control treatment. HBCH3 vineyard was harvested before data could be collected for yield, bunch number, or rot severity.

Figure 1: A row from the trial in a Gisborne Chardonnay vineyard.

PHOTO CREDIT: MARK ALLEN

In the Marlborough shaking time trials, bunch number was not affected by shaking at any time in any vineyard. Yield was unaffected in SB2 and SB3. At the SB1 vineyard, the earlier shaking was carried out, the lower the yield at harvest (Table 2). The date of shaking had no effect on rot at harvest at the SB1 vineyard. At the SB2 vineyard, the later the shake, the less rot at harvest. At the SB3 vineyard, shake 2 had the best effect, with early and later shaking times having higher rot incidence (Table 2). In terms of comparing shaking to sprays, the Marlborough results are similar to Hawke’s Bay and Gisborne, with the sprayed treatment having lower rot at harvest in most cases (Table 2).

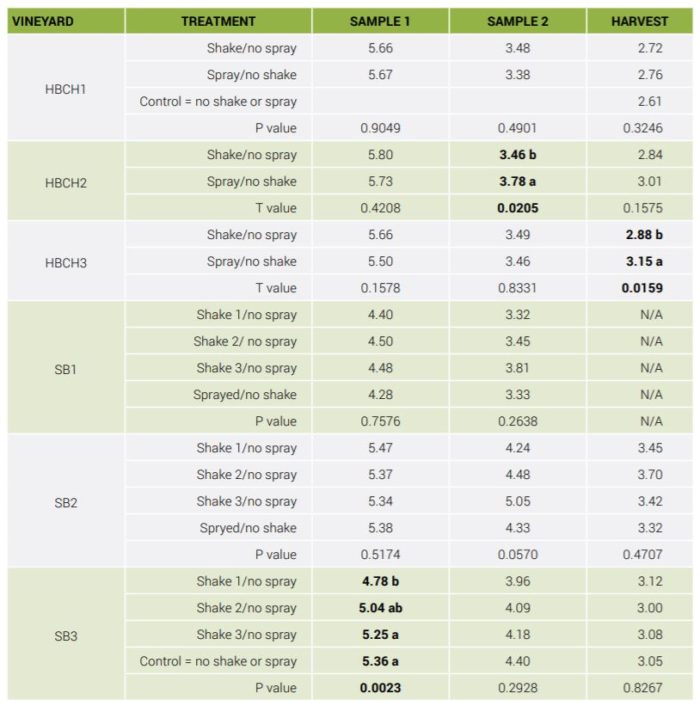

It has been suggested that shaking the fruit causes thicker or tougher skins, and that this, coupled with the floral trash removal, is what leads to the reduced rot that has been observed when shaking is carried out in addition to sprays. Based on skin-break force measurements carried out in Hawke’s Bay and Marlborough this season, this hypothesis is only partially supported. There were few significant differences found in skin toughness, despite large differences in rot severity. Differences in skin toughness did not always correlate with rot severity, meaning tougher skins do not always lead to less rot. For example, at the HBCH3 vineyard, the sprayed treatment had tougher skins and also less rot, however at the SB2 vineyard the sprayed vines had the lowest skin toughness, but also the lowest rot severity (Tables 2 and 3). Future years of the study will help shed light on how skin toughness is affected by shaking, and whether skin toughness has an effect on rot incidence or severity at harvest.

Table 2: Harvest yield, bunch number, and average rot severity of every bunch from Marlborough Sauvignon blanc vineyards. Values in bold with different lower case letters from the same vineyard denote significant differences at the p=0.05 level. At SB3, a sprayed treatment was not carried out, but some vines were left unsprayed and unshaken, which are denoted by the control treatment.

Figure 2: Images of bunches and the trash found in them after the second shake in Marlborough (12/1/19)

PHOTO CREDIT: MARK ALLEN

Conclusion

The data from the first year of the trial has shown that the time of shaking sometimes effects the efficacy of the technique, both in terms of effects on yield, but also on rot severity at harvest. Using botryticide sprays gave better control than shaking the vines alone did, suggesting a single shake cannot entirely replace a chemical spray programme. Shaking had inconsistent effects on skin toughness, and there was not always a correlation between tougher skins and less rot. This finding suggests that the rot reduction seen in previous work using shaking in conjunction with a standard spray programme (Haywood and Allen, 2017) is more likely due to floral trash removal (Figures 2 and 3) and/or a biochemical response than an effect on berry skin thickness or toughness. Future years of this study will shed more light on this possibility.

As the New Zealand wine industry moves towards increased sustainability and a reduction in synthetic chemical inputs, studies such as these investigating how best to use nonchemical techniques will become more and more important. It might be that chemical botrytis sprays cannot be avoided, but that their efficacy can be boosted, or their amounts reduced, by mixing in nonchemical methods alongside chemical control.

Table 3: Skin break force from the Hawke’s Bay and Marlborough vineyards (kgf) using a 2 mm probe tip measured throughout ripening. Sample 1 is shortly after veraison, sample 2 is midripening, and sample 3 is harvest. There was no data collected from SB1 at harvest because the penetrometer was being used in Hawke’s Bay on the day of harvest.

Figure 3: Images of bunches and the trash found in them after the third shake in Marlborough (23/1/19).

PHOTO CREDIT: MARK ALLEN

This article first appeared in the June/July 2019 issue of New Zealand Winegrowers magazine