Daniel Mak, PhD candidate, University of Canterbury

Wineries routinely monitor the changes in wine composition, particularly during fermentation when many biochemical reactions are taking place, to inform the production decisions that determine the overall taste, texture, and quality of the finished wine. Both in-house testing capability and contract wine testing can be costly, particularly when a winery is running multiple ferments.

The University of Canterbury (UC) is collaborating with Bragato Research Institute (BRI) to develop a device that delivers rapid, cost-effective analysis of the components in wine samples without the need for a lab, expensive equipment, or specialist staff training.

The technology: Winealyse

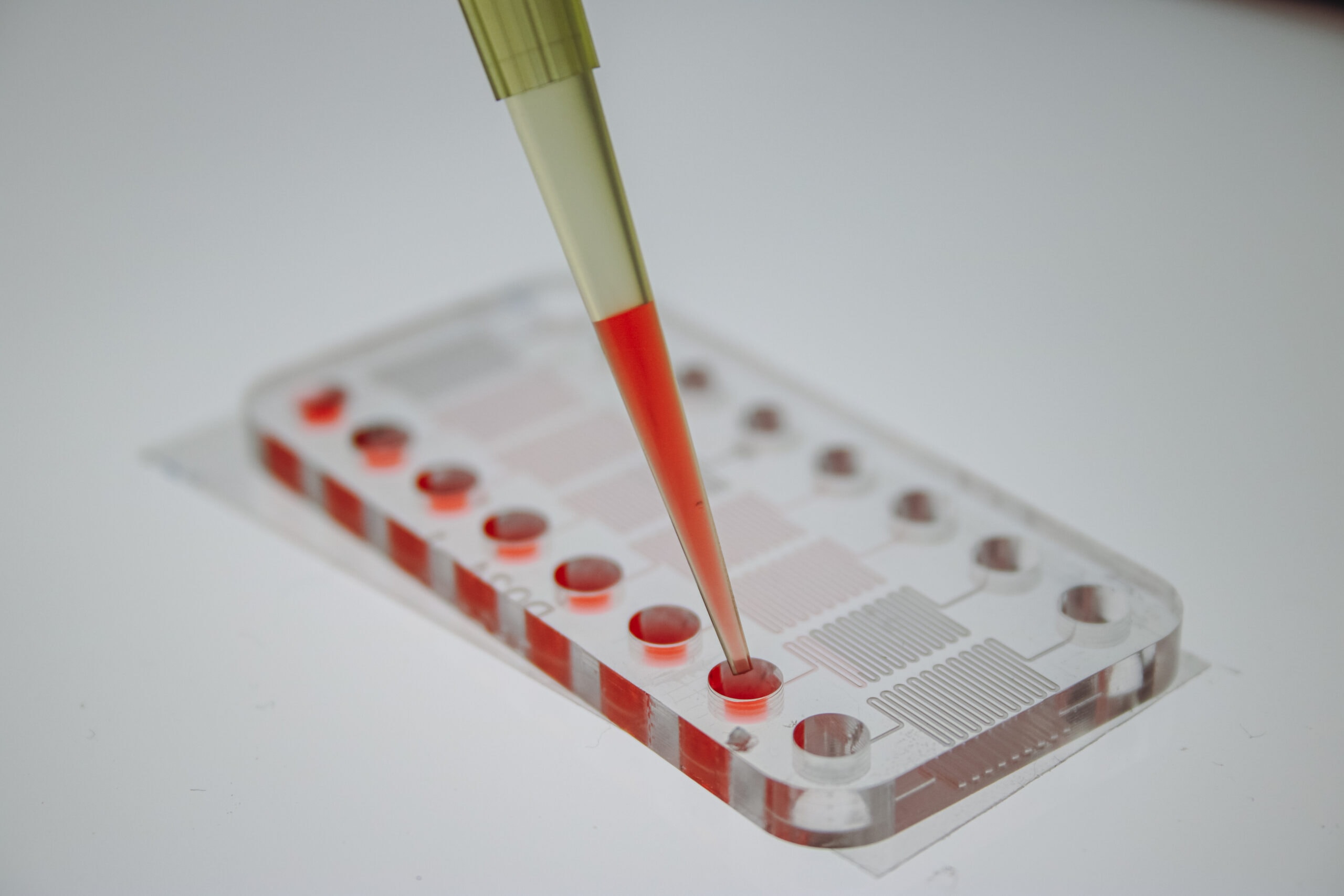

The project, working under the concept name Winealyse, is applying advances in microfluidics to miniaturise traditional laboratory techniques to provide a testing platform that brings wine samples and analytical reagents together on a small ‘chip’ device. The technology applies principles similar to Covid-19 rapid antigen tests (RATs) whereby the analytical chemical reactions happen in the device enabling rapid testing of small sample volumes, on site, and the results can be read within minutes.

How the technology works

The technology Winealyse employs is called ‘capillarics’. While RATs use paper strips to pull the fluids through the test device, capillarics utilises microchannels (0.1-0.25 mm wide x 0.1 mm deep) fabricated in hard materials (chips).

The technology Winealyse employs is called ‘capillarics’. While RATs use paper strips to pull the fluids through the test device, capillarics utilises microchannels (0.1-0.25 mm wide x 0.1 mm deep) fabricated in hard materials (chips).

Sample and reagent solutions are drawn together via capillary action along these microchannels to deliver the required reaction ratio, removing the need for manual handling and pipetting. The team at UC has patented a new type of capillary valve that enables channels to be automatically closed where needed, allowing for devices with more complex functionality to be developed.

This approach significantly reduces the size and training required for the devices, allowing them to be used by anyone, anywhere. This means winemakers and cellar hands can take readings right at the barrel or tank, giving them real-time feedback for more control and understanding of their process.

Prototype testing

The team has now tested a prototype glucose assay using the microchannel chip technology. The device provides a quantitative reading for the glucose concentration in a juice, ferment, or wine sample by presenting a colour change in the reaction. Testing in a working winery environment during the 2023 vintage has shown promising preliminary results for glucose content in juice and wine samples tested throughout the wine production process.

The device is now being further developed for improved robustness, accuracy, and reliability alongside extending the technology to test for a wider range of analytes important to winemakers, including alcohol, sulphur, and TA.

Project recognition

Over the past two years, the team has been fortunate enough to win several awards and be accepted into prestigious programmes. In the UC Innovation Jumpstart competition, the team won the

Greatest Global Impact award, sponsored by Bridgewest Ventures. PhD candidate Daniel Mak was then accepted into the Kiwinet Emerging Innovator programme, a six-month programme that provided Daniel with funding and mentorship to promote his commercial and professional development. The team has won Research Runner-Up in Christchurch NZ’s Food, Fibre, and Agritech Supernode Challenge. Off the back of this, the team was also invited to participate in Sprout Agritech’s Accelerator programme.

How can you help?

The team would like feedback on this project to make sure they can provide the best value to you, the people of the wine industry. Some key questions we have and would appreciate your input on are: what problems do you face in your winery?; What are your testing requirements?; How would you implement a new testing device in your winery; And what would you like to see a test developed for?

If you have any thoughts about these questions or any other aspect of this project, please get in touch with the team via info@bri.co.nz.

About the project

The funding for this project is from the University of Canterbury, Bragato Research Institute, the Ministry for Business, Innovation, and Employment, the MacDiarmid Institute, and Kiwinet. The project team includes PhD candidate Daniel Mak, post-doctoral researcher Dr Azadeh Hashemi and two UC academics – Professor Renwick Dobson and Associate Professor Volker Nock. BRI provides expert guidance on different aspects of testing the components of wine and deep knowledge of the New Zealand industry. The team is passionate about providing a solution to vineyards and wineries for their testing needs. Read more here.